- + AR/AG Glass

- + IP Rate

- + Optical Bonding

- + Wide Operating Temperature

- + Custom-Made

- + Auto-Dimming

What is this technology?

We provide two different choices of optical enhancement solutions that include anti-reflective coated and/or anti-glare protection glass. These technologies can be widely used in outdoor and indoor environment by enhancing optical performance of displays.

How does this technology work?

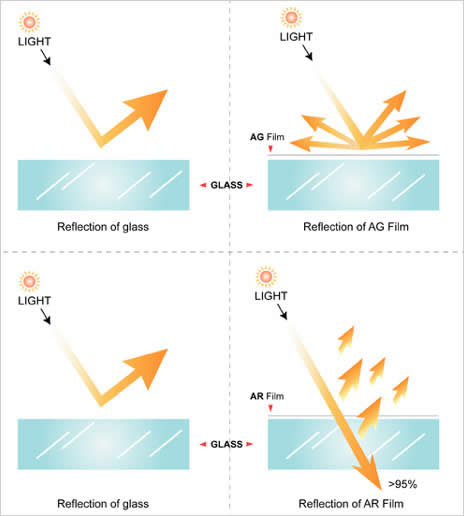

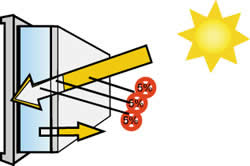

The anti-reflective coatings on the protection glass have excellent performance in tough ambient light conditions. With the normal glass, the strong reflection of the ambient light diminishes visibility and causes problems for viewer. Our special anti-reflective coated protection glass can increase contrast by enhancing light transmission rate over 95% (light reflectance rate less than 5%) and can effectively diminish the mirror images. The multi-layer vapor deposition coating either on one side or two sides of glass is designed to minimize reflectance and maximize transmittance.

Another solution, with an anti-glare (AG) coated protection glass, a microscopically rough surface laminated onto the topmost of display can diffuse glare. The chemically etched glass that has a slightly textured finish can reduce reflection by scattering light directed on its surface. It can soften the image of direct light sources visible in the reflection of the viewing area.

Technology/ Function Diagrams

Advantages of Anti-glare and Anti-reflective protection glass

The anti-reflective coated protection glass can reduce reflection and maximize transmittance. The anti-glare coated protection glass can scatter light directed on the surface and soften the image of direct light sources visible in the reflection of the viewing area. The both can also be tempered glass for vandal proof or even IP65 front

Industrial touch displays with anti-glare and anti-reflective from ITD Technology

ITD provides full sizes of industrial touch displays with anti-glare and anti-reflective protection glasses from 5.7” to 65” mainly used in outdoor or indoor kiosk, outdoor digital signage, ATM, industrial automation, etc.

What is this technology?

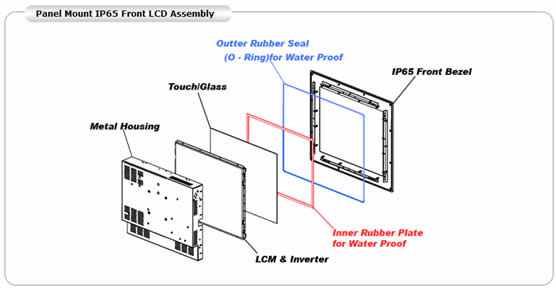

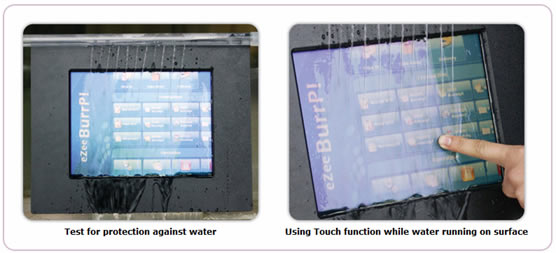

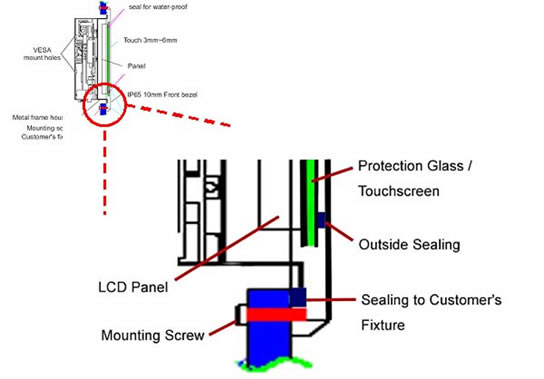

An IP (Ingress Protection) is an international rating which classifies the degrees of protection provided against the intrusion of solid objects and water. IP rating provides full protection against ingress of dusts and water projected from all direction. Industrial and outdoor application demands for IP sealed LCD displays continue to grow.

All of the IP product series goes through the standard testing procedures to test the design reliability. The design meets IP rating whilst maintaining a sleek appearance.

Technology/Function diagram

Advantages of IP Front Industrial Touch Displays

All of our industrial touch monitors can be IP front optional. IP front of ours is reliable and long lifetime design. They are also designed for high reliability, shock and vibration tolerance, survival of high temperature, and corrosive environments. External materials like dust/ water can be very destructive to any type of equipment over time.

The displays have a split pixel design, which allows it to operate without a backlight (reflective mode) in good ambient lighting and in poor lighting.

There is a sensor within the display that tells the display to operate in reflective mode or switch to backlight usage. In poor lighting, the backlight is turned on to properly display the image. This allows the display to be useful in both high and low lighting with best power saving. A well designed optical bonded color LCD can operate and maintain high contrast ratio, even in full sunlight of 100 Klux.

IP Front Industrial Touch Displays from ITD Technology

ITD provides versatile IP grade mechanical design with full range from 6.5” to 55” IP front and tempered glass protection Available for panel mount and rack mount type Integration with thermal and anti-vibration system design capability mainly used in industrial & factory automation, heavy duty vehicles, outdoor Kiosk ,toilet AD display, medical Equipment

Optical Bonding Technology

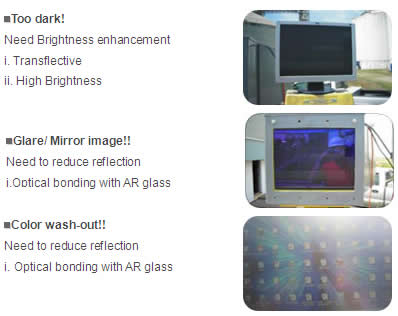

Main Factors affecting Outdoor readability

Why you cannot see the display near the sunlight? We have listed some major factors that affect your display’s readability near sunlight and our corresponding solutions.

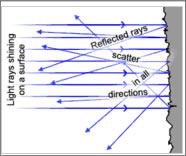

Reflection of light may be specular (that is, mirror-like) or diffuse (that is, not retaining the image, only the energy) depending on the nature of the interface.

Optical bonding helps you to reduce the Reflection Problem

How does Reflection happen?

Optical bonding is mainly dealing with the Reflection. Now let’s look more detail on how reflection happens and the law of reflection. Reflection is the change in direction of a wave front at an interface between two different media so that the wave front returns into the medium from which it originated. Common examples include the reflection of light, sound and water waves.

Reflection of light may be specular (that is, mirror-like) or diffuse (that is, not retaining the image, only the energy) depending on the nature of the interface.

Specular,reflection,source: http://en.wikipedia.org/wiki/Reflection_%28physics%29

Diffuse reflection, source:

http://en.wikipedia.org/wiki/Reflection_%28physics%29

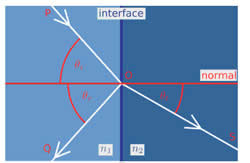

When light moves from a medium of a given refractive index n1 into a second medium with refractive index n2, both reflection and refraction of the light may occur.

Refraction of light waves in water, the dark rectangle represents the actual position of a pencil sitting in a bowl of water. The light rectangle represents the apparent position of the pencil. Notice that the end (X) looks like it is at (Y). A position that is considerably shallower than (X).

Variables used in the Fresnel equations.

- Law Reflection

It states that the direction of incoming light (the incident ray), and the direction of outgoing light reflected (the reflected ray) make the same angle with respect to the surface normal, thus the angle of incidence equals the angle of reflection; this is commonly stated as θi = θr.

- Law of Refraction (Snell's Law)

Snell's law states that the ratio of the sines of the angles of incidence and refraction is equal to the ratio of velocities in the two media, or equivalently to the inverse ratio of the indices of refraction:

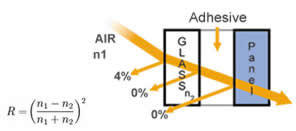

3. How much Reflection happens?

The reflection is caused by the difference between material’s refractive index. The larger the difference, the bigger the reflection happens

- Fresnel equations

When light moves from a medium of a given refractive index n1 into a second medium with refractive index n2, both reflection and refraction of the light may occur.

The fraction of the intensity of incident light that is reflected from the interface is given by reflection coefficient R.

- Calculation of reflection

Refractive index

1. Vacuum air -- 1,

2. II.glass – 1.5

In this case, the reflection coefficient is about 4%.

How Optical bonding can help reduce Reflection ?

- Calculation of reflection:

Refractive index

i. Vacuum air -- 1,

II. glass – 1.5

iii Adhesive – 1.474

The reflection between the glass and the adhesive is close to 0%.

By using the Adhesive whose refractive index is very close to Glass and Panel (Polarizer glass), it can help to reduce the reflection happen when light transmit through glass and panel.

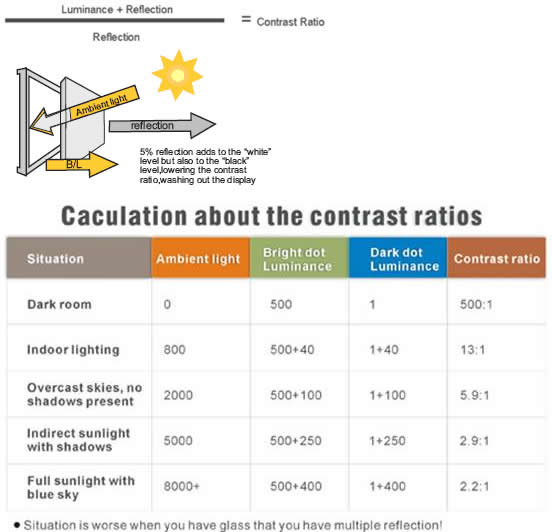

Reduce Reflection help improve Contrast

Now you have known that our optical bonding can help to reduce the reflection. Furthermore, we will show you how the reduction of the reflection and help improve the “extrinsic” contrast ratio and therefore help the outdoor visibility.

“Brightness” lightens or darkens the image. “Contrast” changes the distinction between the light and dark areas.

The human eye eventually becomes saturated with brightness and becomes more responsive to contrast.

Contrast ratio is much more significant than brightness in high ambient illumination environments.

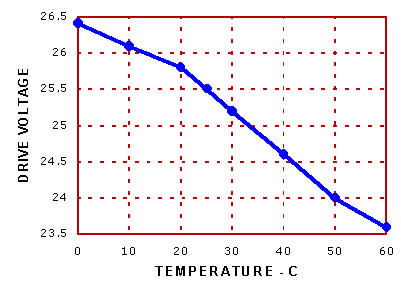

Wide Operating Temperature

What is this technology?

Our selected AUO and CMI TFT-LCD modules and driver board are designed to deliver optimum performance over a wide range of temperatures (Panel operating temp. from -20 to 70 degrees C) in order to accommodate for diverse industrial applications such as outdoor Kiosks in winter and summer in some Northern and Southern countries or areas like Russia, Ice Land, Finland, Poland, India, Egypt, etc.

How does this technology work?

With our heater electronic control mechanism with temperature sensors, the heater control board can control the heater on or off and then regulate the internal system temperature change. (In generally test condition, real case should depend on your panel and mechanical selection).At the low temperature condition, the mechanism starts from pre-heating process and then the LCD panel turn on when its 4 degrees Celsius. When the internal temperature drop below 7 degrees, the heater will be turned on again to keep the system on and keep the temperature above 0 degree Celsius.

On the other side, at the high temperature condition, the mechanism maintains the power switch to protect from overheating. The power will turn off when over 65 degrees C, and will back to turn on status when the internal temperature drop back to 55 degrees. With advanced fan cooling system design, the turn-off temperature can also be applied on this mechanism. Combined with mechanical NMEA/IP degree front bezel and other technical module integration, the wide temperature range system technology shows excellent reliability in harsh environment application.

Technology/ Diagrams

Advantages Of Wide operating temperature

This industrial touch displays with wide operating temperature can work in very harsh environment in very low temperature in Winter or very high temperature in Summer for outdoor. It’s mainly used in outdoor kiosk, theme park POS, industrial automation, and nasty vehicles

Wide operating temperature LCD displays from ITD Technology

ITD provides full sizes of industrial touch displays with wide operating temperature from -20 degrees to 70 degrees including inches 5.7” to 21.5” in open frame, chassis, panel mount, rack mount, panel PC mainly used in kiosks, gaming, ATM, transportation, industrial automation, etc.

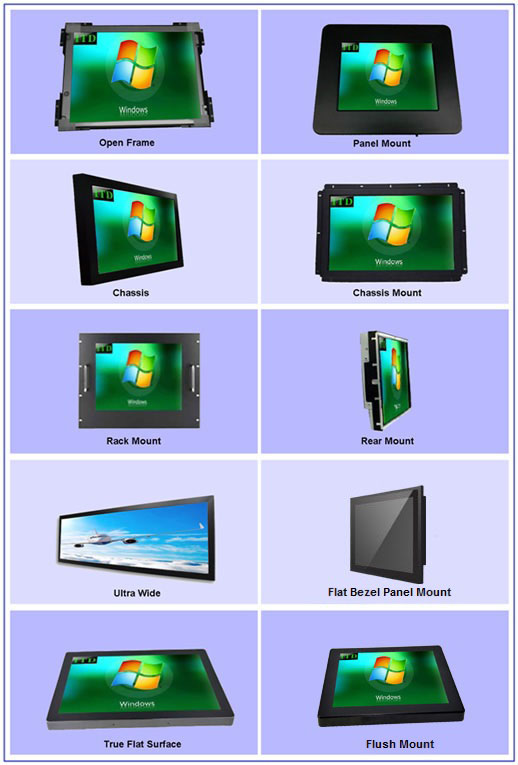

What is this technology?

One of the main features of the industrial display is the diversified demand on the mounting. Those who need industrial displays come from various segments and always have their own unique requirements on how to fix the displays into all kinds of equipments, e.g. ATM, Kiosk, Gaming, Industrial Automation etc. That’s why there are many types of mounting kits designs needed. Our various product lines with different designs of mounting kits can fulfill both standard and non-standard system mounting solutions.

Technology/ Function Diagrams

We use 3D drawing software to analyze if the product mounting is right and no interference. And then we use 2D drawing to demarcate the mounting dimension and directions.

Advantages of Customized Mechanical Design

Reliable and long lifetime proof design

Versatile mounting design with full range from 5” to 82”

Flexible mounting design on different demands

Customized industrial Touch displays from ITD Technology

ITD engineers understand, no matter how thoughtful our designs are, there are always things you need to modify from this base design. That is the reason ITD industrial touch displays is very flexible to modify into your project requirements. ITD sales engineers are standing by to answer your project questions and provide solutions to you.

Auto-Dimming

What is this technology?

It is a sensor that detects light, so if it’s dark, the screen monitor brightness will dim down so you're not looking at one source of extreme bright light. When it’s bright the screen monitor will go up to compensate for the extra light around you, so you can still see the monitor comfortably.

Ambient-light sensor (ALS) ICs are increasingly used in a variety of displays and lighting applications to save power and improve the user experience. With ALS solutions, system designers can automatically adjust display brightness based on the amount of ambient light. Since backlighting accounts for a significant portion of the system's power budget, dynamic brightness control can translate into substantial power savings. It can also improve the user experience, allowing screen brightness to be optimized based on ambient-light conditions.

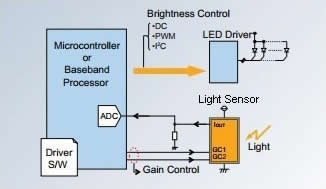

Implementing such a system requires three sections: a light sensor to monitor the amount of ambient light, a device (usually a microcontroller) to process the data, and an actuator to control the current through the backlight.

How does this technology work?

The output of the analog ambient light sensor provides the control input to the system MCU. The processor, in turn, controls the LED brightness based on the lighting environment (The ROHM analog ALS, illustrated here, has two gain control inputs allowing selection of shutdown mode or high, medium or low gain.

Now ITD' standard light sensor design has five-step brightness settings, lightest, Lighter, Normal, Dark, and Darkest.

Steps Panel Specification Display Brightness

|

Steps |

Panel Specification |

Display Brightness |

|

Lightest |

Outdoor/Direct Sunlight |

100% |

|

Lighter |

Cloudy Sky |

75% |

|

|

Indoor with windows or Night with light |

50% |

|

Darker |

Indoor without window |

25% |

|

Darkest |

Night without light or dark room |

Min. |

Advantages of High Brightness LCD Displays With Light Sensor

> Better visual effect in different environment

> Intelligent brightness

> Power saving

High Brightness LCD Displays with Light Sensor from ITD

ITD has developed high brightness LCD displays from 5.7” to 80” in different mechanical designing such as open frame, panel mount, chassis, chassis mount, rack mount, rear mount, true flat surface, panel PC, etc. The light sensor integrated for all models is optional. The length of light sensor cable can be customized so that it can be placed in any position of enclosures or cabinets.

HOME

HOME CONTACT US

CONTACT US WHATSAPP

WHATSAPP